Resources & Documents Library

Laura Dickemann

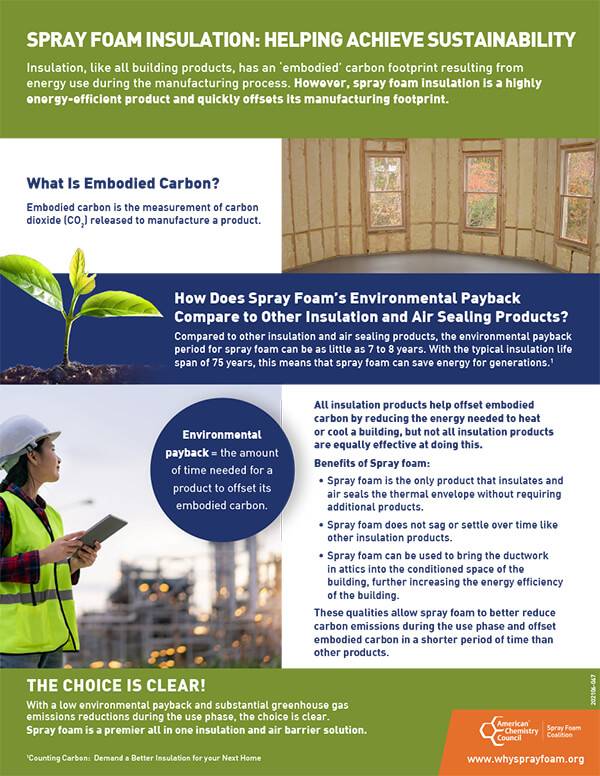

Spray Foam Insulation: Helping Achieve Sustainability

Insulation, like all building products, has an ‘embodied’ carbon footprint resulting from energy use during the manufacturing process. However, spray foam insulation is a highly energy-efficient product and quickly offsets its manufacturing footprint.

Download resource